3D Printing

Training and implementation of 3D printer use.

General description of the project

The implementation of 3D printing in CAPD centers offers new possibilities for creating customized assistive products, adapted educational materials, and accessible recreational devices. Training in the use of these printers allows both professionals and users themselves to design and materialize specific solutions tailored to their needs.

The printed designs were selected and adapted based on the requests of professionals and users, prioritizing the creation of tools that enhance autonomy, accessibility, and participation in daily activities. Usability aspects were also considered, such as differentiated tactile surfaces, Braille labels, and ergonomic pieces to facilitate handling.

Technical breakdown of the project

Through this initiative, a Creality K1 Max AI 3D printer was incorporated into the participating centers, selected for its printing speed, large build volume (300×300×300 mm), and ease of use—features that make it a versatile, safe, and reliable tool for institutional contexts. Its closed system, automatic calibration, and intelligent error detection enable intuitive operation and high-quality results without requiring advanced technical knowledge.

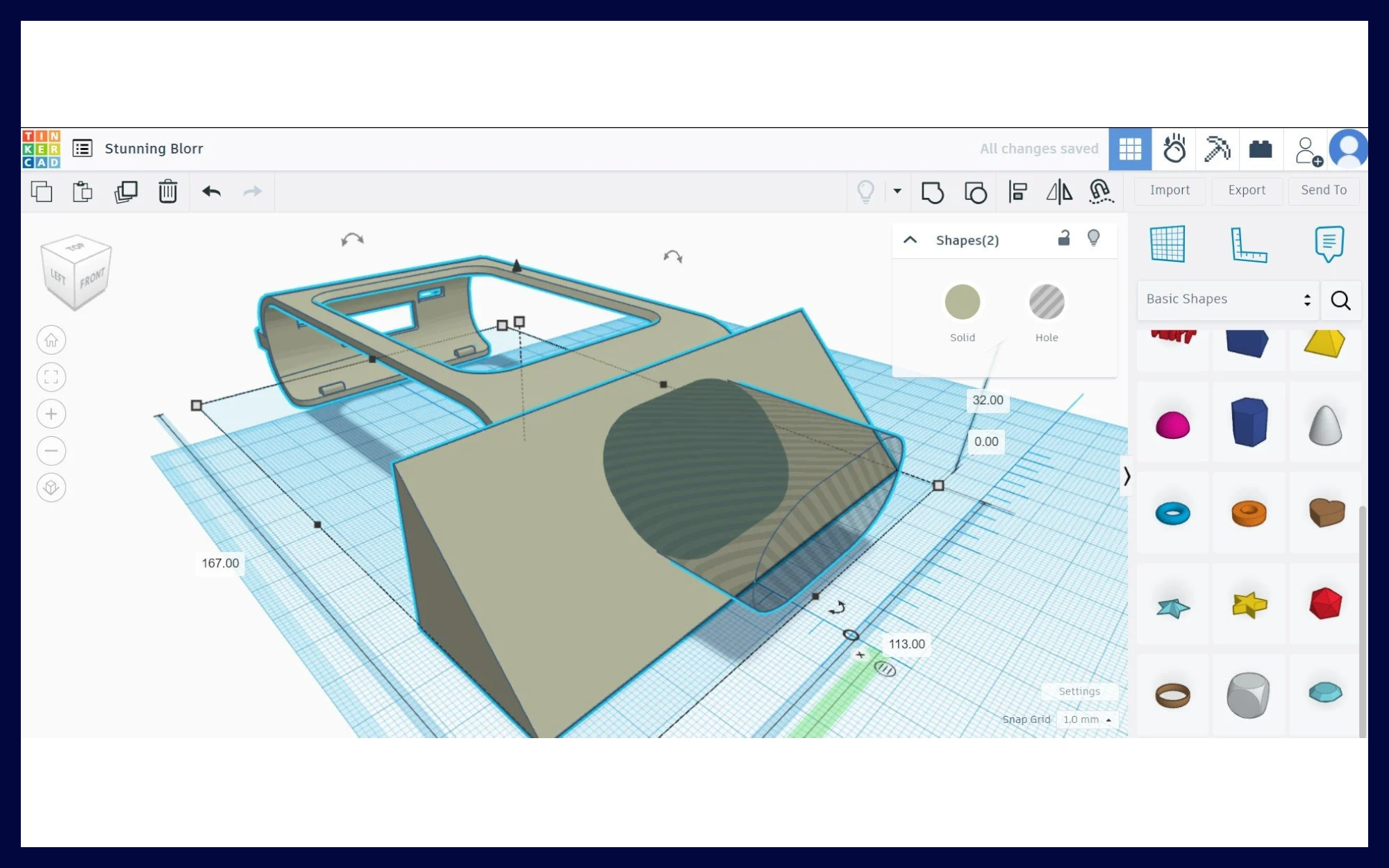

For model design, the TinkerCAD program was chosen—an online tool that stands out for its visual and intuitive interface, ideal for introducing users to 3D design and fostering collaboration among professionals with different levels of experience. Its simplicity facilitates the creation of functional adaptations and prototypes tailored to the specific needs of each center.

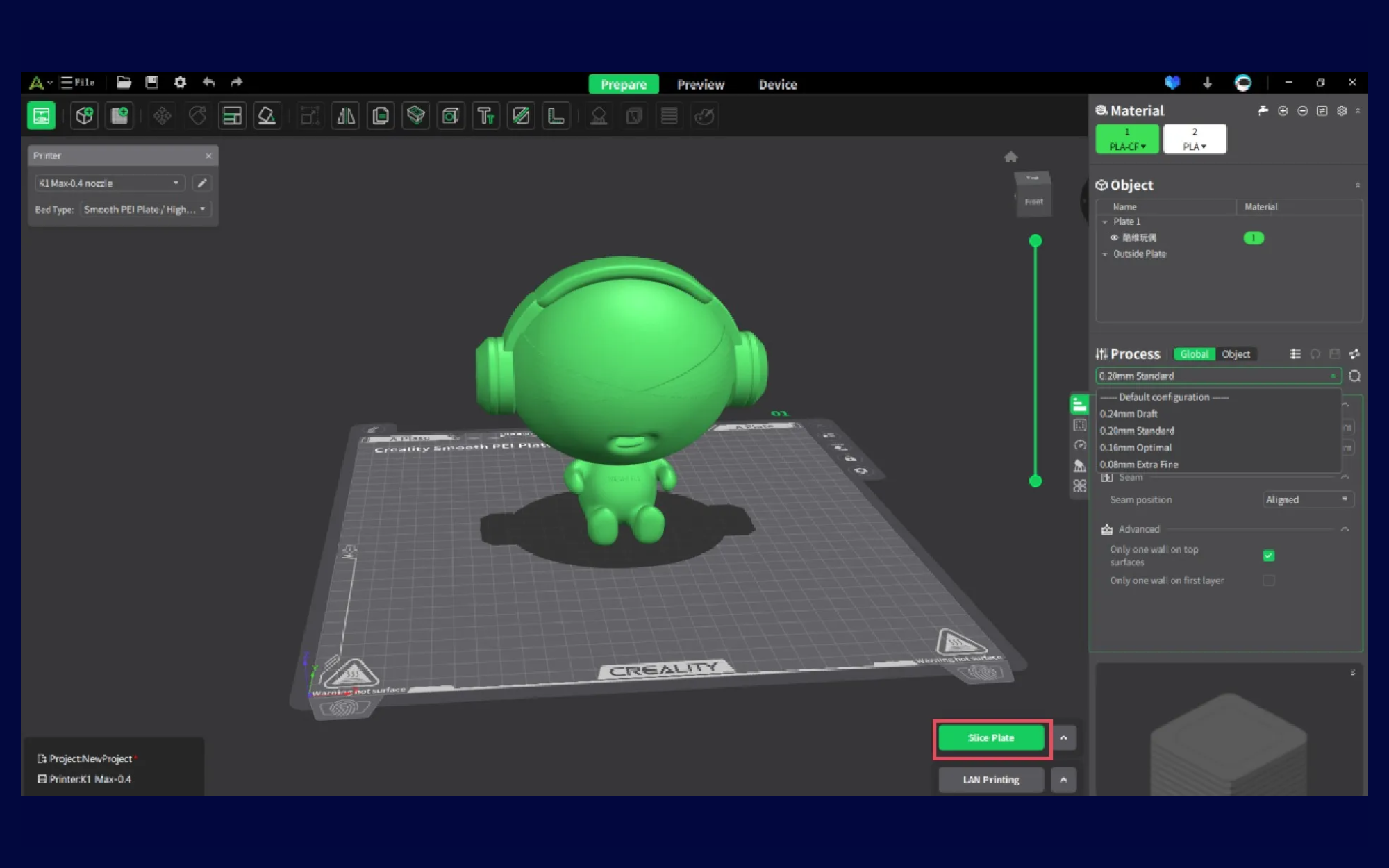

The printing preparation process is carried out using Creality Print software, which offers direct integration with the K1 Max model and allows easy configuration of slicing parameters, ensuring stable and precise prints.

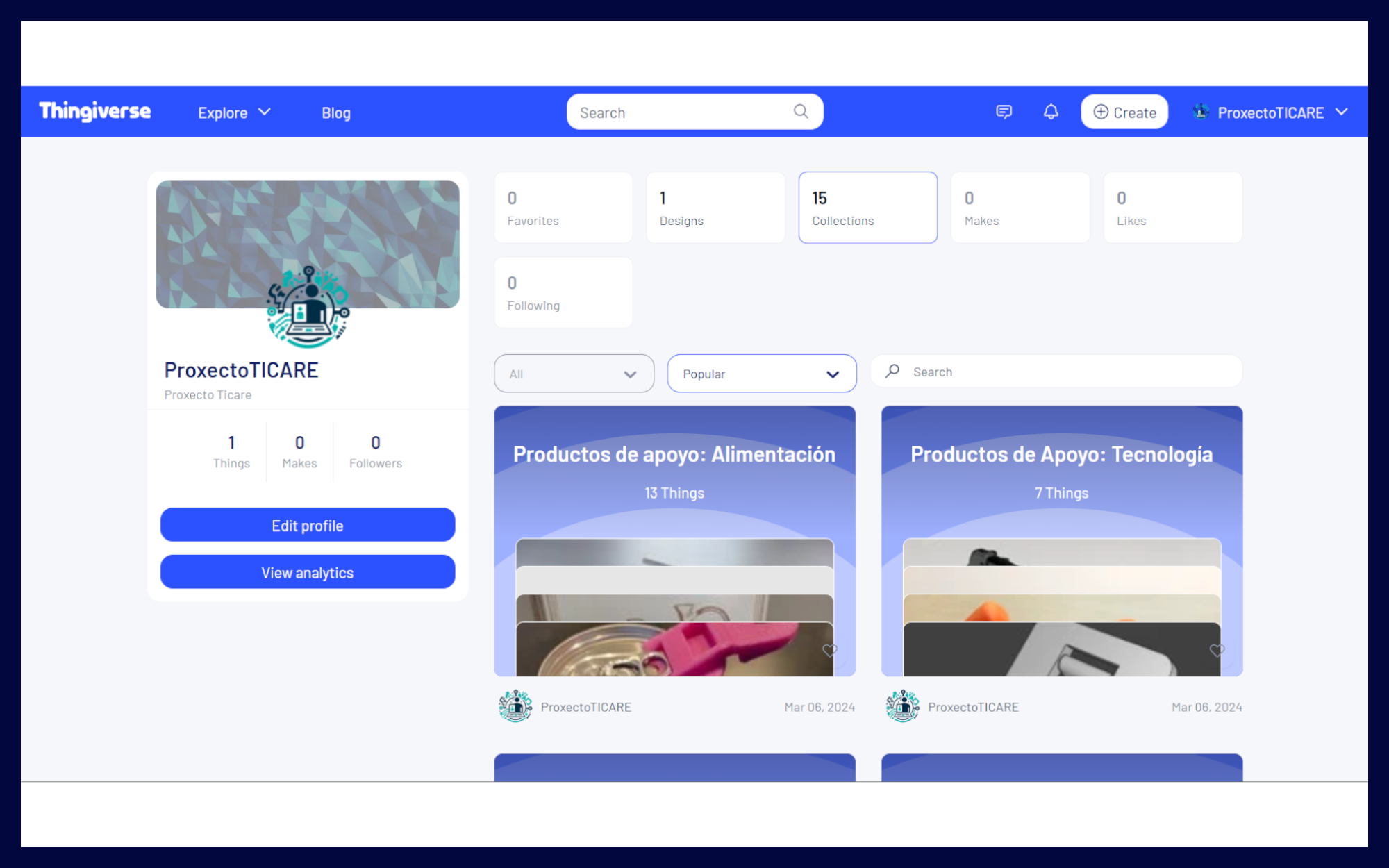

Additionally, the project promoted the creation of a shared model repository on the Thingiverse platform, organized into categories of interest for the centers, such as daily living activities, leisure, communication, or utensil adaptations. This collaborative space encourages the exchange of designs and experiences and helps build a shared knowledge network among the different work teams.

To ensure proper technology implementation, the project included specific training sessions tailored to the professional profiles of each center, covering everything from design and slicing software use to basic equipment maintenance. In parallel, customized manuals were developed, detailing work procedures and practical examples to facilitate the integration of 3D printing into each institution’s educational and therapeutic routines.

Team

- Paula de Santos Dorrego, occupational therapist, TALIONIS research group

- Raúl Fraiz Gómez, occupational therapist

- Manuel Lagos Rodríguez, computer engineer, TALIONIS research group

- Jorge Rivadulla Brey, computer engineer, TALIONIS research group

- Iago Fernández Garrido, computer engineer, TALIONIS research group